This handy approach pronounced duh-may-ik is the key to employing Six Sigma and beginning your journey to being a process hero. Six Sigma juga sering disimbolkan menjadi 6σ.

Lean Six Sigma Bisnis Siap Berkompetisi Pt Multi Global Unity

Lean Six Sigma Bisnis Siap Berkompetisi Pt Multi Global Unity

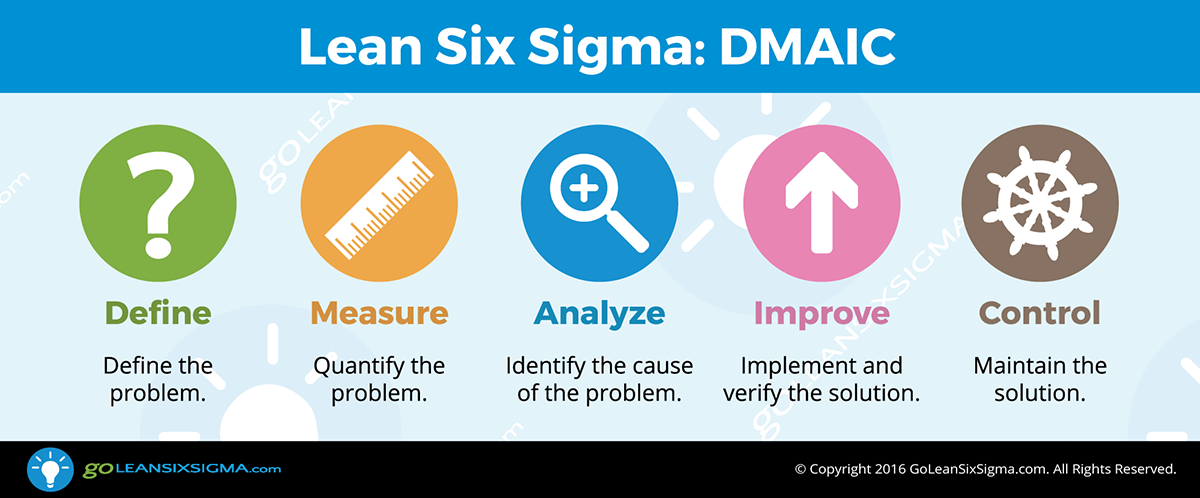

Define measure analyse improve and control DMAIC.

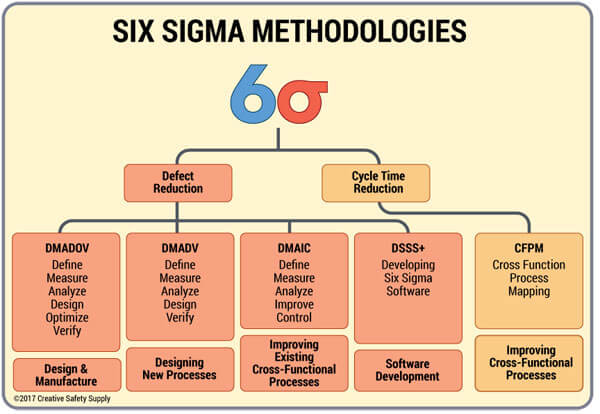

Six sigma dmaic. It also recommends how Six Sigma projects should be managed and describes the roles. Pengertian Six Sigma Six Sigma adalah metode yang berfokus pada peningkatan kualitas SIX SIGMA berasal dari kata SIX yang berarti 6 dan SIGMA yang merupakan satuan dari Standar Deviasi yang dilambangkan dengan simbol σ. It consists of five phases.

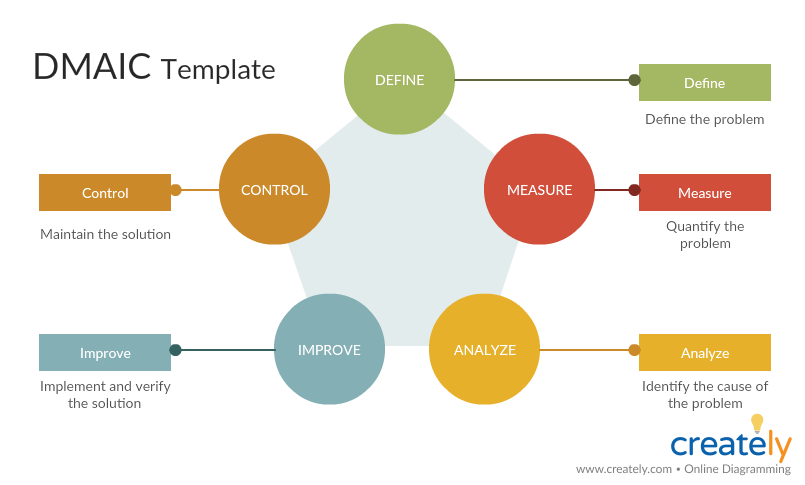

Plenty of organisations use this model for improvement because it consists of 5 main phases which are Define Measure Analyze Improve and Control DMAIC. Six Sigma is a systematic problem solving approach that is centered around defects elimination and variation reduction which leads to process improvement. These phases are Define Measure Analyze Improve and Control otherwise known as DMAIC.

Were going to cover each step in the process and detail how to effectively enact every section. Define measure analyze improve and control. Particularly DMAIC is a logical framework that helps you think.

Ketika kita mau melakukan improvement. Each letter stands for a phase in the DMAIC process. Also see DMAIC Overview.

DMAIC is an acronym that summarizes a Lean Six Sigma methodology for solving difficult problems with existing processes. Measure adalah fase kedua DMAIC tentunya ada banyak hal yang bisa kita lakukan di fase ini. One of the principal tools in Six Sigma is the use of the DMAIC methodology.

Done properly the five phases associated with Lean Six Sigma LSS projects can deliver significant sustainable process improvements. DMAIC an acronym for Define Measure Analyze Improve and Control pronounced də-MAY-ick refers to a data-driven improvement cycle used for improving optimizing and stabilizing business processes and designs. DMAIC is a five-step method for improving existing process problems with unknown causes.

Lean Six Sigma is simply a process for solving a problem. If the Six Sigma quality improvement methodology had to be summarized in one word it would be the acronym DMAIC. Tujuan utama fase ini adalah untuk mendapatkan gambaran secara detail mengenai proses atau area yang menjadi fokus improvement kita.

Terdapat dua metode yang bisa kita pilih untuk menerapkan Six Sigma di perusahaan yaitu DMAIC dan DMADV. However DMAIC is not exclusive to Six Sigma and can be used as the framework for other. The methodology typically comprises five phases.

Define Measure Analyze Improve Control. One of the core techniques behind any process improvement particularly in Six Sigma is DMAIC. This shorthand description lists the steps of the Six Sigma process when improving existing business processes.

Kedua metode ini tentu memiliki fungsi yang berbeda. This process is also known as DMAIC duh-may-ik its acronym. The DMAIC improvement cycle is the core tool used to drive Six Sigma projects.

Fase Measure dalam Lean Six Sigma DMAIC. ISO 13053-12011 recommends the preferred or best practice for each of the phases of the DMAIC methodology used during the execution of a Six Sigma project. It provides an overview of the method by which Six Sigma projects are completed namely.

The phases provide a structure that makes success more likely. Nah perbedaan inilah yang akan kita bahas di artikel SHIFT kali ini.