The focus is on process variations and emphasis is given to customer satisfaction. The principles of Six Sigma are executed through methodologies or roadmaps to improvement like a workflow.

The Six Sigma expert uses qualitative and quantitative techniques to drive process improvement.

Six sigma techniques. It provides methods to improve efficiencies in a business structure improve the quality of the process and increase the bottom-line profit. Six Sigma tools are defined as the problem-solving tools used to support Six Sigma and other process improvement efforts. Six Sigma is a data-driven problem-solving methodology.

Six Sigma is a data-driven methodology that provides tools and techniques to define and evaluate each step of a process. Although the tools themselves are not unique the way they are applied and integrated as part of a system is. This leads to a myth that Lean is easier than Six Sigma because the visual analysis of Lean is easy to understand while many people are intimidated by Six Sigmas numerical analysis.

The primary toolset includes a. Six Sigma Techniques. Memiliki tujuan untuk menghilangkan cacat produksi memangkas waktu pembuatan produk dan mehilangkan biaya.

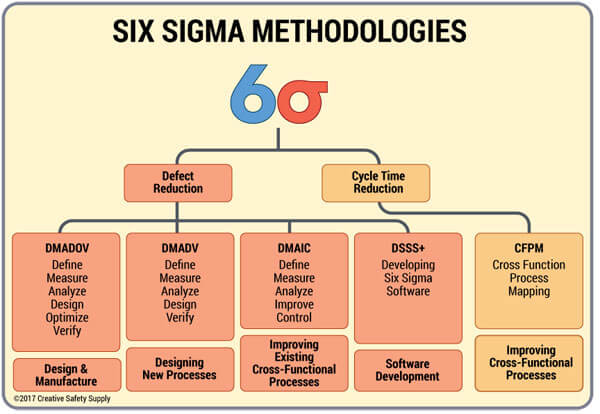

Methods Tools Techniques are vital to the success of any Six Sigma project whether DFSS or DMAIC. When a Six Sigma venture is undertaken in a corporation it follows outlined the sequence of steps and worth targets which might be quantified equivalent to growing buyer satisfaction and revenue whereas lowering air pollution the course of time and price. Two main methodologies are DMAIC and DMADV.

Let us briefly review what do we mean by these keywords. Every stage of a Six Sigma project recipe requires a mix of these methods tools techniques. DMAIC pronounced duh-may-ick focuses on incrementally improving existing processes.

Nowadays Six Sigma refers to a combined Lean and Six Sigma methodology for quality-control. Learning the Lean Methodology first gives momentum to solve problems by. It is the most widely known methodology and the one most associated with Six Sigma.

Continuous process improvement with low defects is the goal of this method. The Six Sigma methodology also uses a mix of statistical and data analysis tools such as process mapping and design and proven qualitative and quantitative techniques to achieve the desired outcome. Six Sigma primarily uses statistical techniques for analysis and solution creation that are supported with data visualization.

And by using Six Sigma Motorola became a Quality leader also won the prestigious Malcolm Baldrige National Quality Award in 1988 after that the secret of Motorolas success became public knowledge and then onwards Six Sigma revolution was started. The Lean method is for achieving stability whereas the Six Sigma is for increasing optimization. Six Sigma Techniques Six Sigma methodology incorporates many powerful tools to use in continuous improvement projects and programs.

Six Sigma adalah suatu alat manajemen baru yang digunakan untuk mengganti Total Quality Management TQM sangat terfokus terhadap pengendalian kualitas dengan mendalami sistem produksi perusahaan secara keseluruhan. Six Sigma is a disciplined data-driven approach and methodology for eliminating defects driving toward six standard deviations between the mean and the nearest specification limit in any process -- from manufacturing to transactional and from product to service. The Goal of Six Sigma.

The method uses a data-driven review to limit mistakes or defects in a corporate or business process. After Motorola many companies like Allied signal General electric implemented this methodology and produced. Key Six Sigma Techniques in use.

Six Sigma is a quality-control methodology developed in 1986 by Motorola Inc. Six Sigma technique employs varied methods of quality management similar to statistical strategies.