A few of the main symbols are. About Bernie Roseke PEng PMP.

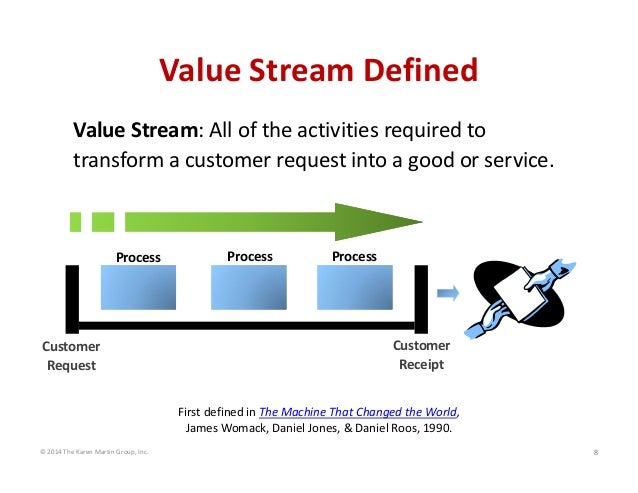

What is Value-Stream Mapping Value stream may be a new phrase in your vocabulary.

Value stream analysis. Value stream maps are also one of the tools from Lean manufacturing. Value stream analysis involves drawing up a process flow chart for the business and then asking at each stage including the stages between activities whether costwaste or value is being added. VSM makes clear the time and effort being spent on non-value adding activities the cost of doing business and sets the stage for reducing waste and streamlining the process.

Value stream analysis separates those activities that contribute to value creation from activities that create waste and identifies opportunities for improvement. Its a tool for reducing waste and improving efficiency with the goal of providing optimum value to customers in the form of products or services. In this way it is different from a value chain which is usually defined over broad functional areas rather than a specific product.

Also known as material and information-flow mapping it uses a system of standard symbols to depict various work streams and information flows. The value stream represents the steps taken to deliver the specific product or service. Improvements value stream mapping analysis strengthens the gains by providing vision and plans that connect all improvement activities Value stream mapping analysis is a tool that allows you to see waste and plan to eliminate it.

1 the production flow from raw material into the. Value stream mapping is a lean manufacturing or lean enterprise technique used to document analyze and improve the flow of information or materials required to produce a product or service for a customer Increase the value delivered by your software factory with Plutora. Value streams may be generated a number of ways.

Value Stream Analysis VSA is a key tool of Lean Thinking. As with other business process mapping methods it helps with introspection understanding your business better as well as analysis and process improvement. Value stream mapping is a lean management tool that helps visualize the steps needed to take from product creation to delivering it to the end-customer.

VSM visualizes the flow of a single product or service from supplier to customer with the aim of identifying delays and processes that dont add value. Value stream mapping sometimes called VSM is a lean manufacturing technique to analyze design and manage the flow of materials and information required to bring a product to a customer. Value Stream Analysis What is it.

It is a simple assessment of where value is added and where non-value waste accumulates in a process. Value stream maps use standard methodology and symbols to communicate the creation of value creating activities. Value Stream Analysis In lean theory the value stream refers to all of the actions required to bring a product or service from concept or raw material to finished good.

By the 1990s value stream mapping has been used in more worldwide sectors and fields from manufacturing to software development. Value Stream Analysis is a powerful planning tool to optimize the result of eliminating waste. Latter value stream mapping analysis became popular with the development of the Lean process management in the 20th century and was used by many leading companies such as Toyota.

A value stream map uses symbols to represent the flow of information and inventory within a system and to streamline those processes. Each action contributes value to the finished product ideally working together efficiently to create a continuously flowing stream of value. These are the main symbols used in the creation of value stream maps but the comprehensive list of standard symbols can result in a highly communicative value stream map.

As the focus of the value stream includes the complete value adding and non-value adding process from conception of requirement back through to raw material source and back again to the consumers receipt of product there is a clear need to extend this internal. A value stream is all the actions both value added and non-value added currently required to bring a product through the main flows essential to every product. The value stream is the entire collection of activities necessary to produce and deliver a product or service.

Value Stream Mapping Steps Of The Value Stream Mapping Process Value Stream Mapping Process Map Business Process Management

Value Stream Mapping Steps Of The Value Stream Mapping Process Value Stream Mapping Process Map Business Process Management

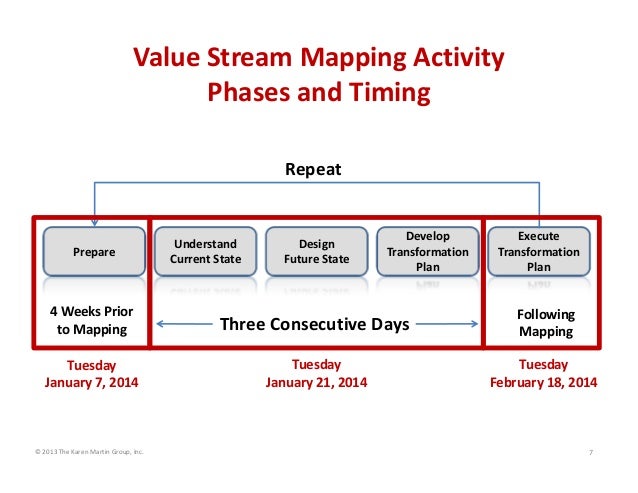

Value Stream Mapping Charter Scope

Value Stream Mapping Charter Scope

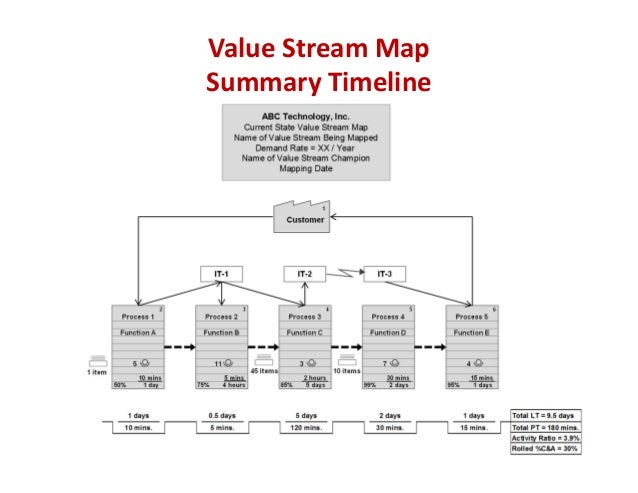

Value Stream Map Summary Timeline

Value Stream Map Summary Timeline

Value Stream Map Summary Timeline

Value Stream Map Summary Timeline

Value Stream Analysis When Fisherman And Dried Fish S Producer Is Download Scientific Diagram

Value Stream Analysis When Fisherman And Dried Fish S Producer Is Download Scientific Diagram

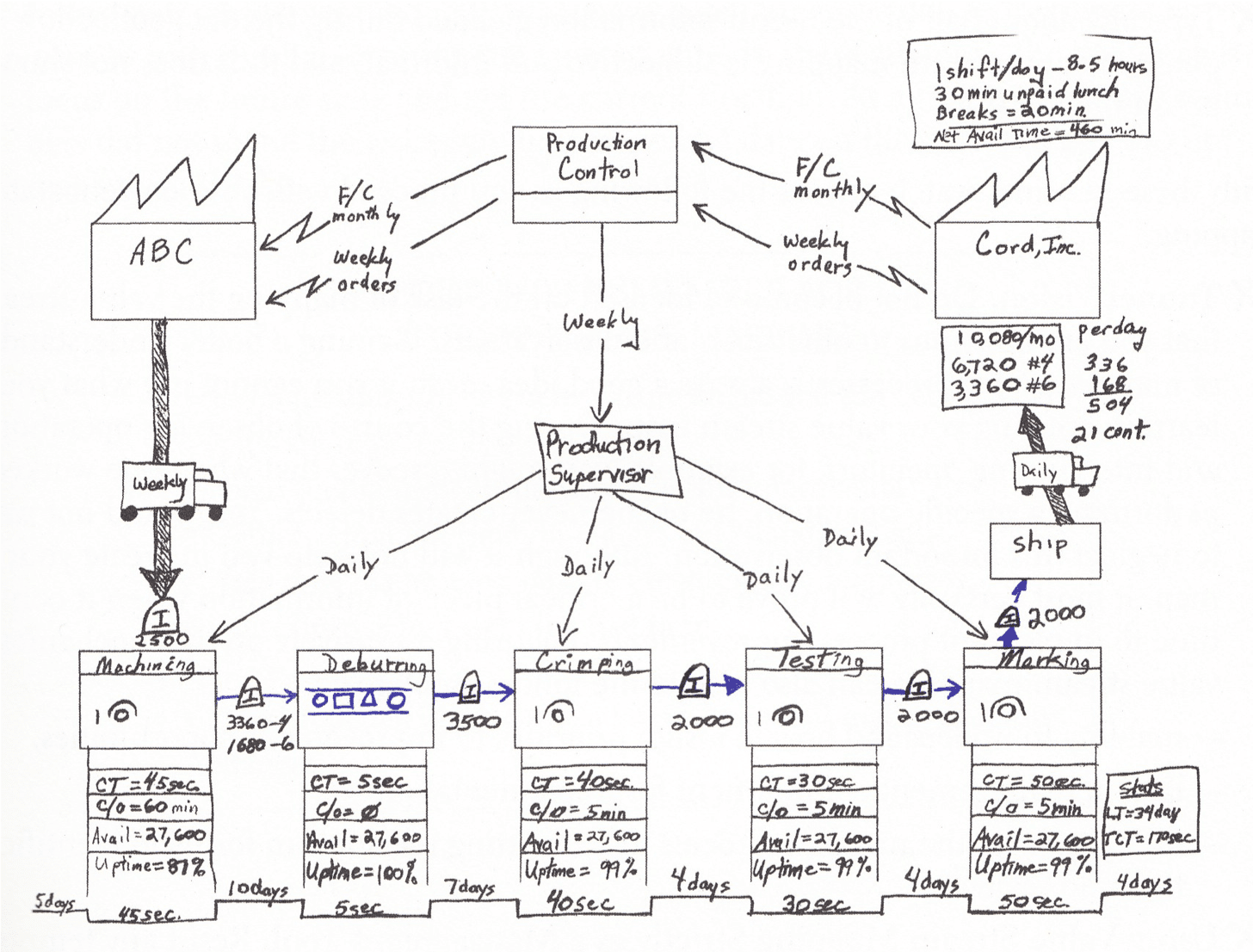

Value Stream Mapping Wikipedia

Value Stream Mapping Wikipedia

What Is Value Stream Mapping Vsm Benefits Process And Value

What Is Value Stream Mapping Vsm Benefits Process And Value

Mifd Lean Manufacturing And Six Sigma Definitions

Mifd Lean Manufacturing And Six Sigma Definitions

The Orieginal Value Stream Mapping Vsm Root Cause Analysis

The Orieginal Value Stream Mapping Vsm Root Cause Analysis

Seeing The Value Of Value Stream Mapping Catalyst Consulting

Seeing The Value Of Value Stream Mapping Catalyst Consulting

Value Stream Mapping Templates To Quickly Analyze Your Workflows

Value Stream Mapping Templates To Quickly Analyze Your Workflows

Misconceptions About Value Stream Map

Misconceptions About Value Stream Map

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.